Innovations in Laminated Nonwoven Fabric Technology

Introduction

In the vast realm of textile engineering, laminated nonwoven fabrics are a product of true genius. These engineered textiles combine the strength, versatility, and robustness of nonwoven fabrics with the superior functional benefits of lamination. Over the years, ongoing innovation in this space has led to the development of advanced laminated nonwoven fabric technologies. This article will delve into these technological advancements, revealing how they have revolutionized numerous industries and our daily lives.

An In-depth Look at Laminated Nonwoven Fabrics

Before delving into the technological advancements, let’s understand the basics of laminated nonwoven fabrics. As a fundamental break from traditional textiles, nonwoven fabrics are not produced by knitting or weaving. Instead, these fabrics are made from webs or sheets of fibers, bound together through friction, adhesion, or cohesion, using manufacturing methods like spunbond, meltblown, needlepunch, and hydroentanglement.

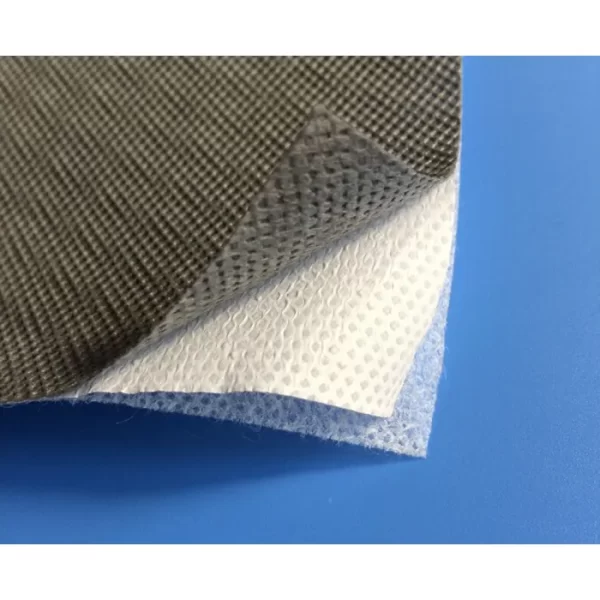

The lamination process further refines nonwoven fabrics, introducing an additional layer of functionality. The term lamination refers to the technique of manufacturing a material in multiple layers to achieve enhanced strength, stability, and other specific characteristics. The lamination of nonwoven fabrics usually involves the application of heat and pressure, and this combination results in a fabric that exhibits an impressive blend of the advantages of the original nonwoven fabric and the laminating material.

Laminated nonwoven fabrics have risen in popularity due to their notable properties. They exhibit high tensile strength, superior stability, and commendable resistance against moisture, bacteria, abrasion, and UV radiation. As a result, they have become a material of choice for numerous industries, bringing us to the current era of continued innovations in laminated nonwoven fabric technologies.

Disruptive Innovations in Laminated Nonwoven Fabric Technology

As the textile industry continues to evolve, a slew of pioneering innovations has emerged, disrupting traditional manufacturing methods and redefining the possibilities of laminated nonwoven fabric applications.

1. Nano-engineered Nonwoven Fabrics

Nanotechnology, the manipulation of matter on an atomic, molecular, and supramolecular scale, has provided a significant leap forward in nonwoven fabric engineering. Nano-engineered nonwoven fabrics are designed by incorporating nano-fibers into the fabric structure during the manufacturing process. These nano-fibers dramatically improve the fabric’s capabilities, offering high filtration efficiency and superior barrier properties, which make these materials vital in healthcare for the production of protective clothing and face masks, amongst other things.

2. Biodegradable Nonwoven Fabrics

In response to the escalating global concerns about environmental sustainability, the textile industry has made significant strides in developing biodegradable nonwoven fabrics. Unlike traditional fabrics that can take hundreds of years to decompose, biodegradable nonwoven fabrics are engineered to break down under specific environmental conditions, thereby reducing the environmental footprint of textile products. The raw materials for these fabrics are often derived from renewable sources, further enhancing their eco-friendly nature.

3. Smart Nonwoven Fabrics

The fusion of textile engineering and digital technology has given rise to smart nonwoven fabrics. These materials are embedded with electronic components and sensors that can interact with the user or environment. With the ability to measure parameters like temperature, heart rate, and moisture levels, smart nonwoven fabrics have found application in various fields, including healthcare, sports, and wearable technology. They are expected to play a significant role in the wearable technology revolution, enhancing our interaction with our environment in ways previously unimagined.

4. 3D Printing and Nonwoven Fabrics

3D printing, or additive manufacturing, has transformed many industries, and textiles are no exception. This technology enables the creation of nonwoven fabrics with complex geometrical shapes and structures, unlocking a myriad of unique functionalities and designs. In the medical field, for instance, 3D-printed nonwoven fabrics could be used to create custom implants or prosthetics, offering better fit and comfort.

5. Self-cleaning Nonwoven Fabrics

Another remarkable innovation in this sector is the advent of self-cleaning nonwoven fabrics. Engineered to repel dirt and stains, often through the application of nanotechnology, these fabrics can maintain their cleanliness for longer durations, reducing the frequency of washing and maintenance required. This property makes self-cleaning nonwoven fabrics a potential game-changer in industries such as healthcare and hospitality, where maintaining cleanliness is critical.

The Road Ahead for Laminated Nonwoven Fabrics

The continuous advancements in laminated nonwoven fabric technology, from the development of sustainable materials to the advent of smart, interactive fabrics, represent the future of textile engineering. This evolution is not only reshaping multiple sectors but also the way we interact with our environment.

As we look ahead, it’s clear that the potential applications of these fabrics are immense and far-reaching. From revolutionizing the fashion and healthcare industries to paving the way for sustainable textile solutions, the future of laminated nonwoven fabric technology holds immense promise.

In this rapidly evolving industry, it’s vital to stay updated with the latest developments. To keep up with the groundbreaking innovations in laminated nonwoven fabric technology, consider subscribing to our newsletter and following us on social media. As we navigate this fascinating landscape together, we anticipate unlocking new possibilities and redefining the world of textiles.

Please visit our website for more product details https://medposnonwoven.com/product-category/non-woven-fabrics/